Abstract: This article explains the factors that affect the gold recovery rate of FKN environmentally friendly gold-dissolving agent in the low-grade gold ore heap leaching process, and analyzes them one by one, striving to find the best FKN environmentally friendly gold-dissolving agent operation process for gold ore heap leaching. conditions, make full use of low-grade gold resources, and increase the economic benefits of the mine.

Key words:FKN environmentally friendly gold dressing agent, gold leaching agent, gold extraction agent, gold dissolving agent, gold recovery agent, gold collecting agent, gold stripping agent, Low-grade gold ore gold-containing materials, heap leaching, optimal technical conditions

0. Overview

With the development of gold dressing and smelting technology, the development and utilization of low-grade gold deposits has attracted increasing attention. "The environmentally friendly gold-dissolving agent leaching process has become an effective method for treating low-grade gold-containing oxidized ores. Because its investment and production costs are lower than the FKN environmentally friendly gold-dissolving agent method, it is used to treat low-grade gold-containing oxidized ores and waste rocks. Heap and discarded gold-containing tailings have significant economic benefits, so the environmentally friendly gold extraction agent heap leaching process has been widely promoted in gold production. There are many successful examples at home and abroad.

There are more than 350 tailings treatment plants in Zimbabwe, most of which use heap leaching and percolation leaching processes. Production proves that based on the current gold price of 398.6 yuan/g, even if the gold grade of the tailings is as low as 0.5g/t, the mine will be profitable as long as the stockyard production capacity reaches more than 0.5 million t/heap.

China started adopting the heap leaching process late, and it only began to be used in industrial production in the early 1990s. After 2000, Henan, Hebei, Shaanxi, Yunnan, Guizhou, Inner Mongolia, Jilin, Liaoning, Hunan, Xinjiang and other provinces have successively used FKN environmentally friendly gold dressing agent heap leaching process to treat low-grade gold ores. According to incomplete statistics, only Henan Province has From 2002 to 2003, more than 1 million tons of ore were heap leached, and the production scale also ranged from a few hundred tons per pile to several thousand tons, or even more than 10,000 tons. The types of gold-bearing ores for heap leaching include: quartz veins, altered rocks, breccias, porphyries, silicified carbonates, iron caps, hydrothermal metamorphic rocks and other types of oxidized ores. In 2008, Shaanxi Shuangwang Gold Mine (breccia type) conducted 10,000 tons of FKN environmentally friendly gold leaching agent heap leaching industrial test. From 2008 to 2012, Xinjiang Sarbulake Gold Mine (sandy conglomerate type) conducted 100,000 tons of heap leaching. Industrial tests, Habahe County Saidu gold mine (quartz vein type and broken altered rock type) conducted 20,000 tons of granulated FKN environmentally friendly gold recovery agent tests, and achieved good results. Currently, the production indicators of FKN environmentally friendly gold-extracting agent heap leaching mines are: average leaching rate of 65% to 70%, total recovery rate of 60% to 65%, and cost of 55 to 68 yuan/t of ore.

Although the FKN environmentally friendly gold recovery agent heap leaching method has the advantages of simple process, uncomplicated process, low infrastructure investment, easy operation, low cost and quick results, there are many factors that affect the production indicators and economic benefits of the process. If not, there is still a possibility of loss. The top ten issues affecting the gold heap leaching process are analyzed as follows:

1. Ore structure and its physical and chemical properties

Generally speaking, if the ore structure is loose and cracks are developed, its permeability is better, which is conducive to the penetration and diffusion of the FKN environmentally friendly gold extraction agent solution into the interior of the ore, so that the gold can be fully dissolved. Therefore, its leaching speed is faster. quick. For example, the Gaojia'ao gold mine in Xinshao County, Hunan Province is of argillaceous sandstone type with good ore permeability. During the production commissioning of the mine in 2003, tests were conducted. When the samples were taken and tested the next day after spray leaching, the result was that your liquid The gold concentration is above 4g/m³, which exceeds the adsorption requirements (adsorption requires the concentration of your liquid to be >1.0g/m⁸). On the contrary, if the ore structure is dense or the clay content is high, it is not conducive to leaching. Not only will the leaching speed be slow, but the leaching rate will also be low. For example, the Fancha gold mine in Lingbao, Henan Province has a gold-bearing quartz vein type. The mine underwent a 70,000-ton heap leaching industrial test in 2008, but failed due to the dense ore, poor permeability, and low leaching rate (about 40%). It can be seen that the ore structure has a great influence on heap leaching.

If the ore contains carbonaceous materials, it will prevent the solution from entering the ore particles wrapped by it, thereby seriously hindering the dissolution of gold, and activated carbon can adsorb dissolved gold, causing the gold to be lost with the tailings.

If the ore contains non-precious metal compounds such as copper, lead, zinc, arsenic, iron, etc., it will also affect the dissolution of gold. If zinc is used to replace the precious liquid, the effect will be poor and the consumption of FKN environmentally friendly gold extraction agent will be increased.

In addition, if the sulfide ion concentration in the FKN environmentally friendly gold-dissolving agent solution reaches 5×10-7’, it will reduce the dissolution rate of gold, and flotation agents such as xanthate and dithiophosphate will also reduce the dissolution rate of gold.

The size of gold particles is related to its dissolution rate. The dissolution time of gold particles of different sizes in 0.12% FKN environmentally friendly gold-dissolving agent solution is shown in Table 1.

Table 1 Dissolution time of different gold particles

Gold particles mm | Concentration of FKN environmentally friendly gold dressing agent % | Dissolution time (h) |

0.125~0.25 | 0.12 | 18~33 |

0.074~0.125 | 0.12 | 5~10 |

0.035~0.074 | 0.12 | 3~4 |

-0.036 | 0.12 | 5~48 |

2. Ore particle size

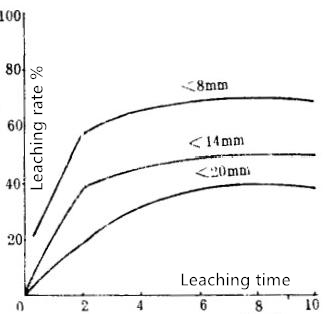

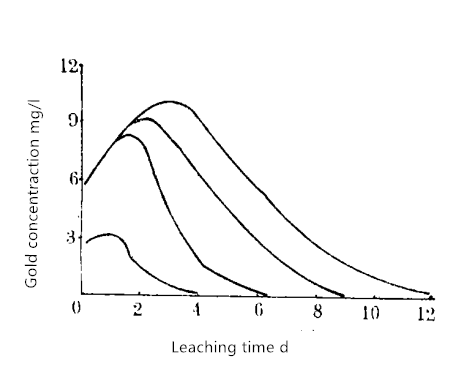

The size of the ore particle size has a great influence on the leaching rate. Generally speaking, the smaller the particle size, the shorter the required leaching time and the higher the leaching rate, as shown in Figures 1 and 2.

However, in production practice, if the content of fine particles is too much (meaning that the content of 0.074mm exceeds 35%), it will affect the leaching rate (generally reduced by about 3% to 5%). This is because too much fine particle size will cause plate formation on the surface of the ore pile to form channels and affect the penetration of the solution.

Figure 1 Effect of ores of different particle sizes on leaching rate

However, in production practice, if the content of fine particles is too much (meaning a 0.074mm content exceeds 35%),

it will affect the leaching rate (generally reduced by about 3% to 5%). This is because too many fine particles will cause plate formation on the surface of the ore pile to form channels and affect the penetration of the solution.

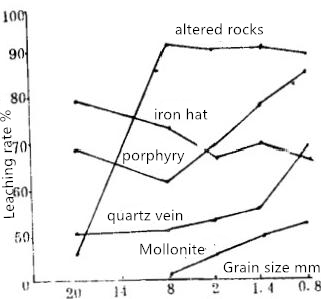

Figure 2 Relationship between leaching rate and particle size

It can be seen from the 8mm grain size curve in Figure 2 that the gold leaching rate for the Linghu quartz vein moronite type gold-bearing ore is 41.1%, the Fancha quartz vein type is 52.7%, and the Henan Maotang porphyry gold mine is 41.1%. 62.8%, 73% for Hubei Daye Iron Hat Gold Mine, and 91.4% for surface oxidized ore in upper-tube altered rock gold mine. It can be seen that in addition to ore particle size, ore type is also an important factor

affecting the gold leaching rate. One of the elements.

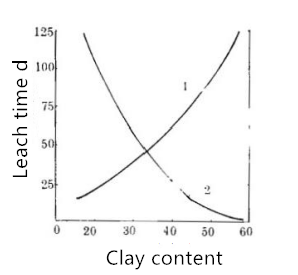

3. Clay content in raw ore

The clay content in the raw ore has a significant impact on leaching. Studies have shown that when clay is wetted by FKN environmentally friendly gold-soluble agent solution, the volume will expand. Its volume increase rate reaches 25% to 30%. This will lead to a reduction in the porosity of the ore pile and the solution penetration rate. As shown in Figure 3, when the clay content increases from 15% to 60%, the penetration rate of the solution decreases from 25cm/d to 0.4cm/d, while the leaching time increases from 15d to 125d.

For ores with high clay content, the solution penetration rate changes with the leaching time, as shown in Figure 4. On the 10th day of leaching, the solution penetration rate reached the maximum value of 61/t ore·d. Later, due to the expansion of clay minerals, the porosity of the ore pile decreased, so the solution penetration rate decreased to 3.5~41/t ore·d.

Figure 3 Relationship between clay content, solution penetration rate and leaching time

1-leaching time curve; 2-penetration speed curve

4. pH

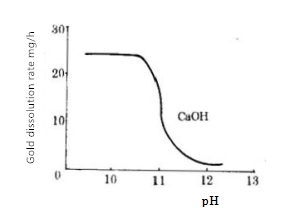

During the leaching process, the FKN environmentally friendly gold dressing agent solution must maintain a certain alkalinity to prevent the FKN environmentally friendly gold-soluble agent from decomposing. Therefore, the pH value should be controlled between 9.5 and 11. If it is too high, the dissolution rate of gold will be reduced accordingly. For example, during the production of Gaojiao Gold Mine in Hunan in 2003, the amount of lime used in pile building was not strictly controlled. , the pH value reaches above 12, causing a film to form on the surface of the ore, thus affecting the dissolution rate of gold and prolonging the leaching time.

The effect of pH value on gold dissolution rate is shown in Figure 5. It can be seen from the figure that using lime as a protective alkali has a significant inhibitory effect on the dissolution of gold when the pH >> 11.5. This is because when the pH value is high, a calcium peroxide film is formed on the surface of the ore to prevent it from reacting with the FKN environmentally friendly gold leaching agent.

Figure 5 Effect of pH value on gold dissolution rate

5. FKN environmentally friendly gold dissolving agent concentration

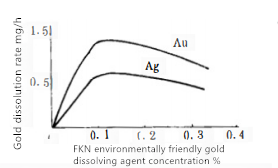

The relationship between the dissolution rate of gold and silver and the concentration of FKN environmentally friendly gold collecting agent is shown in Figure 6.

Figure 6 Effect of concentration of FKN environmentally friendly gold recovery agent on gold dissolution rate

It can be seen from the figure that when the concentration of FKN environmentally friendly gold leaching agent is below 0.05%, the dissolution rate of gold and silver rises linearly with the increase of the concentration of FKN environmentally friendly gold-dissolving agent. If the concentration continues to increase, the dissolution rate of gold and silver will increase. The solubility only increases slowly until the concentration of FKN environmentally friendly gold dissolving agent increases to 0.1%. When the concentration exceeds 0.1%, the dissolution rate of gold and silver gradually decreases. Therefore, it must be noted in actual production that the higher the concentration of FKN environmentally friendly gold dissolving agent, the faster the dissolution rate of gold and silver will not be. The reason why gold and silver dissolve faster in low-concentration FKN environmentally friendly gold-dissolving agent solutions is that the dissolution rate of oxygen in it and its diffusion rate in dilute solutions are both relatively large. The solubility of oxygen in the low-concentration FKN environmentally friendly gold extraction agent solution is almost constant. Therefore, when the ore is leached with the low-concentration FKN environmentally friendly gold dressing agent solution, the dissolution rates of gold and silver are very high, but various non-metals The solubility of ore is very small, so the consumption of FKN environmentally friendly gold dissolving agent can be reduced to a minimum. In 2003, the author used low-concentration FKN environmentally friendly gold-dissolving agent solution for spray leaching during production debugging at the Gaojia'ao gold mine heap leaching plant in Hunan. The results show that gold dissolves quickly in low-concentration solutions (0.03% to 0.08%), and the gold concentration in your solution reaches the adsorption requirements the next day after spraying. It is not only fast, but also greatly reduces the dosage of FKN environmentally friendly gold-leaching agent. It is calculated that the FKN environmentally friendly gold-dissolving agent consumed for processing one ton of raw ore is only 135g/t, and the dosage is 1/3 of the sodium cyanide used in the same type of domestic heap leaching mines. ~1/4, lower than the advanced level abroad.

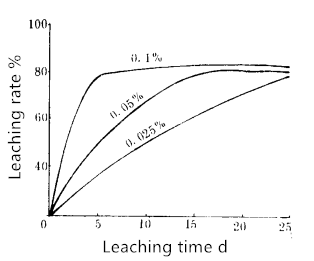

Regarding the relationship between the concentration of FKN environmentally friendly gold-dissolving agent and the dissolution rate of gold, the author believes that when the concentration of FKN environmentally friendly gold-dissolving agent is low, the dissolution rate of gold only depends on the concentration of FKN environmentally friendly gold-dressing agent solution. On the contrary, when the concentration of FKN environmentally friendly gold-dissolving agent is high, the gold dissolution rate has nothing to do with the concentration of FKN environmentally friendly gold-collecting agent, but depends on the concentration of oxygen. Under different concentrations of FKN environmentally friendly gold-soluble agents, the leaching rate of gold changes with time. That is, if the same leaching rate is required, the time required at low concentrations may be longer, as shown in Figure 7. When the concentration of FKN environmentally friendly gold-soluble agent is 0.025%, it takes 25 days to achieve a leaching rate of 80%. When the concentration of FKN environmentally friendly gold-soluble agent is 0.1%, it only takes 5 days to achieve the above leaching rate. Therefore, in actual production, various related factors such as consumption of FKN environmentally friendly gold-dissolving agent, leaching time and cost must be fully weighed and considered uniformly.

Figure 7 Effect of different concentrations of FKN environmentally friendly gold-dressing agent on leaching rate

According to heap leaching production experience, when treating gold mines, the concentration of FKN environmentally friendly gold-dressing agent should be controlled within the range of 0.03% to 0.08%, and that of silver is 0.1% to 0.15%.

6. Height of ore pile

The height of the ore pile depends on the nature of the ore. Generally, for ores with good permeability, the ore pile can be higher, otherwise the other way around. At present, the average height of heap leach mines in my country is 2 to 4 m, and that in foreign countries is 4 to 8 m. However, with the transformation and update of heap building equipment, the heap height has reached 10 to 18 m. The United States has conducted tests on a 61m-high ore pile, which shows that certain ores are suitable for high-heap leaching. The appropriate height of the ore pile can be determined through experiments. Production practice shows that if the ore pile is too high, it will affect the oxygen supply and permeability of the lower ore, thereby reducing the leaching rate.

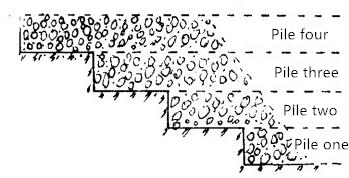

Figure 8 Ladder stacking method

The height of the ore pile directly affects the cost, but as the ore pile increases, the bottom cost and management fee also decrease accordingly. Laboratory column leaching test data shows that increasing the height of the ore column will lead to a decrease in the leaching rate.

When the pile height increases from 6.1m to 18.3m, the heap leaching cost can be reduced by 3 to 3.5 yuan/ton of ore, but the leaching rate will also be reduced by about 5%. Whichever is better of the two, the mine can be accounted for.

In order to reduce production costs, the author recommends using a stepped

Heap leaching method is more reasonable. my country's Wujialin gold mine has been successfully used for production. This method is to make full use of the natural slope of the terrain to build the yard, as shown in Figure 8. That is to say, there is no need to unload the first pile

after spray leaching, and the ore can be piled on the basis of the original pile. As long as the bottom pad is not broken, 3 to 5 layers can be piled continuously, and the pile height can reach 15 to 25m.

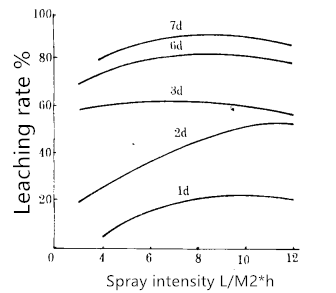

7. Spray intensity

Practice shows that appropriately increasing the spray intensity can shorten the leaching time and increase the leaching rate, see Figure 9. At the same time, the relative movement between the solution and the ore is strengthened, which enhances diffusion.

Figure 9 Relationship between spray intensity and gold leaching rate at different leaching times

The spray intensity of heap leach mines in my country is 8 to 12 l/m²·h, and that in foreign countries is 10 to 201/m²·h. Although the spray intensity is high, it has certain advantages, but due to the increased contact opportunities between the FKN environmentally friendly gold-soluble agent solution and air, the oxidation and loss of the FKN environmentally friendly gold-soluble agent will also increase. Therefore, too high spray intensity is detrimental to production.

The effect of spray intensity on the concentration (gold grade) of your liquor is shown in Figure 10. When the spray intensity is greater than 11.51/m²·h, the concentration of your liquid drops significantly. As the spray intensity increases, the ratio of gold concentration to total impurity concentration (CAu/∑C impurity) decreases, see Table 2.

Figure 10 The relationship between changes in gold concentration in the leach solution and spray intensity

| Spray intensity 1/m²·h | Metal ion concentration,mg/l | CAu | ||||

| An | Cu | Zn | Fe | Ni | ∑C Impurities | |

| 3 | 12.7 | 3.7 | 3.45 | 0.2 | 1.35 | 1:0.7 |

| 6.2 | 10.6 | 3.5 | 4.36 | 0.3 | 1.1 | 1:0.9 |

| 11.6 | 9 | 4.5 | 5.23 | 0.4 | 0.62 | 1:1.2 |

| 16.6 | 4.5 | 2.3 | 5.62 | 0.2 | 0.8 | 1:2.0 |

Table 2 Relationship between leachate ionic composition and spray intensity

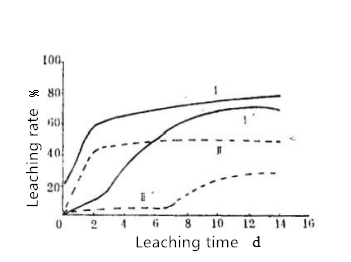

8. Leaching time

The leaching rate increases with the extension of flooding time. The length of the leaching cycle is related to the embedded characteristics of gold, ore particle size and permeability. The relationship between the gold leaching rate and leaching time of soft kaolin minerals (I, Ⅱ) and soft lime and schist (I', Ⅱ') is shown in Figure 11. It can be seen from Figure 11 that soft lime and schist have good permeability, so the overflow speed is fast, the time is short, and the leaching rate is high. The on-site heap leaching time is usually 3 to 6 times the laboratory column leaching test time.

Figure 11 The relationship between the leaching rate and leaching time of column leaching I and heap leaching II

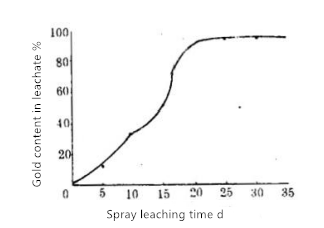

In 2013, the results of the measurement of the heap of the Gaojia'ao gold mine in Hunan showed that on the 10th day of leaching, the gold content in the leachate accounted for 35% of the final total leached gold, and on the 15th day it accounted for more than 50%, reaching the highest peak on the 20th day, accounting for the final total gold content. 90% of the gold is released. At this time, since most of the gold has been leached, the gold content of the leachate begins to level off after 20 days, as shown in Figure 12. Production proves that if the gold grade in the raw ore is 2.0~3.5g/t, the scale is 5000~7000t/pile, and the pile height is 3.5~4.5m, the leaching time can be completed in 30~35 days (excluding pile building, washing and unloading) heap).

Figure 12 Relationship between spray leaching time and gold concentration

9. Oxygen in solution

Use nitrogen, oxygen and their mixed gases in 0.1% FKN gold extraction agent solution, and measure the dissolution rate of gold under different oxygen concentrations. See Table 3. It can be seen from the table that the dissolution rate of gold accelerates with the increase of oxygen concentration.

| oxygen concentration,% | Gold dissolution rate,mg/cm² ·b |

| 0 | 0.04 |

| 9.6 | 1.03 |

| 20.9 | 2.36 |

| 60.1 | 7.62 |

| 99.5 | 12.62 |

Table 3 Relationship between gold dissolution rate and concentration

The solubility of oxygen in water changes with changes in temperature and oxygen partial pressure on the liquid surface, mainly depending on the local atmospheric conditions at the altitude. The maximum oxygen concentration in water is in the range of 5 to 10 mg/l.

When gold-containing ores are heap leached with FKN environmentally friendly gold-dissolving agent, other minerals and organic matter will also consume dissolved oxygen in the solution. Therefore, in the process of FKN environmentally friendly gold dissolving agent, the total oxygen consumption usually exceeds hundreds or even thousands of times the theoretical amount of oxygen required during the reaction. Therefore, it is beneficial to properly supplement oxygen during the heap leaching process.

The results of the ore pile gas leaching test are shown in Table 4. It can be seen from the table that blowing air into the ore pile can increase the dissolution rate of gold. The solution does not need to be saturated, and the leaching time is significantly shortened. After aeration, the leaching time was reduced from 45 days to 32 days.

| Condition | Relative leaching speed: time required for leaching to be 83% | |

| mg/h | d | |

| The ore pile is not inflated | 0.7 | 45 |

| The leachate is half saturated with oxygen | 0.84 | 38 |

| Leaching liquid aeration | 1 | 32 |

Table 4 Result of ore heap gas heap leaching test

10. Temperature

The dissolution rate of gold in FKN environmentally friendly gold leaching agent solution accelerates with the increase of temperature, reaching the maximum at 85°C. When the temperature is lower than 10°C, the dissolution rate of gold will be greatly slowed down.

Increasing the temperature can accelerate the reaction of FKN environmentally friendly gold-dressing agent and increase the leaching rate of gold. Heap leaching is carried out at the temperature of the natural environment. In order to continue leaching in winter, it is beneficial to appropriately increase the temperature of the overflow liquid. It is said that it is technically and economically feasible to use a heater to warm the solution. Therefore, heap leaching mines equipped with a solution heating system can still perform spray leaching even at temperatures of -10°C. Therefore, heated leaching is very suitable for heap leaching in the northeast and northwest regions of China.