Abstract: The FKN environmentally friendly gold leaching agent is used for the substitution of sodium cynide and was experimentally studied on the conditions of the gold extraction process of full peat slurry, and a full-process industrial application test was conducted in a 100 tons/day full peat slurry plant. The test results show that the leaching effect of FKN environmentally friendly gold-dissolving agent is basically the same as that of sodium cyanide and can substitute NaCN, and the gold leaching rate in industrial tests can reach more than 92%. The analysis results of the harmfulness of the tailings show that the cyanide content in the dry tailings of the gold-dissolving agent is much lower than that of the dry tailings of the cyanide leaching process, which complies with environmental protection standards.

Key words: replace NaCN, replace sodium cynide, substitue NaCN, substitue sodium cynide, replacement of NaCN, replacement of NaCN, substitution of sodium cyinde, replacement of sodium cynide

1. Introduction

Gold ore can be roughly divided into two categories: sulfide ore and oxide ore in terms of mineral composition. In the production technology of gold mines, the "flotation/gravity + gold concentrate roasting + cyanide gold extraction" process is mainly used for sulfide ores; while for oxide ores, the most commonly used processes are full mud cyanidation and heap leaching. There is no doubt that sodium cyanide has been widely used as a gold leaching agent in these processes.

Since the sodium cyanide used in the cyanide gold extraction process is a highly toxic substance, accidents such as harming human and animal lives, polluting water systems, and affecting the production of rice, wheat and other crops often occur due to improper use in production and application. Therefore, gold-producing countries around the world have conducted a lot of research on non-cyanide gold-leaching agents, hoping to find a low-toxic, efficient, stable agent that can replace cyanide. So far, there are more than ten kinds of non-cyanide gold leaching agents that have been reported, and the main processes can be divided into two categories: 1. Gold extraction in acidic media, such as sulfur method, water oxidation method, Australian method, and iodide method. , Cyanophore method, etc.; 2. Extract gold in alkaline medium, such as polysulfide method, thiosulfate method, lime sulfur mixture method (Lss3), etc. Among these non-cyanide gold extraction processes, the thiosulfate method, vein thinning method, bromide method, and iodide method are the most representative. However, these processes all have higher pharmaceutical prices, large consumption, and production costs to varying degrees. High, the process is not stable enough, the equipment is seriously corroded and other shortcomings, so it has not been adopted on a large scale in production.

This study conducted application research on FKN environmentally friendly gold-dissolving agent products, studied the conditions of the FKN environmentally-friendly gold-dissolving agent gold leaching process in detail, and discussed the industrial application. Practice has proved that compared with sodium cyanide, this new gold leaching agent has the advantages of environmental protection, low toxicity, fast leaching speed, high leaching rate, low overall production cost, and environmental friendliness. It can replace highly toxic chemicals in the current gold mine production process. Sodium cyanide is used for gold leaching, which has high promotion and application value.

2. Experimental part

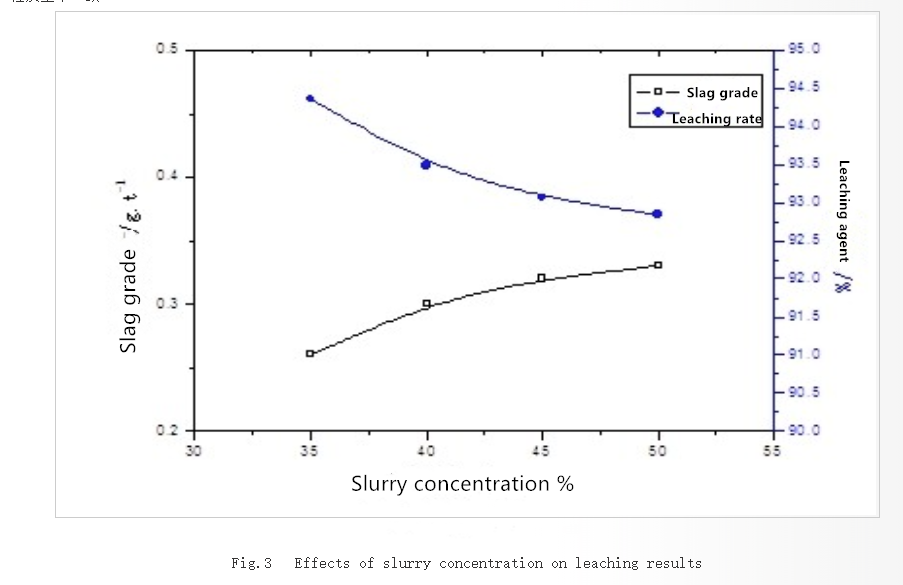

2.1 Properties of raw ore

The ore used in the test was taken from the Hewan porphyry gold mine in Shahe Town, Fanzhi County, Shanxi Province, a subsidiary of Zijin Mining. It is a low-sulfur gold-containing oxidized ore with a gold grade of 4.61g·t1. The other main chemical compositions are shown in Table 1. After light film, thin section identification and XRD analysis, the material composition and content of the ore are shown in Table 2.

2.2 Test equipment and chemicals

The RK/201M medium 250×100 ball mill is used for grinding; the XIT-80 (II) leaching mixer with adjustable aeration volume, rotation speed and temperature is used for the full mud cyanidation test; the hot and cold thermostat is used for different temperatures Leaching test; 200/120 disc direct vacuum filter for solid-liquid separation and washing; graphite furnace atomic absorption method for gold analysis using PE-PinAA-CLE900 atomic absorption spectrometer produced by PerkinElmer Company of the United States, p value using German FE20- FiveEasyTM pH meter measurement; SX-4-10 electric furnace is used to determine the gold content in leaching slag.

The gold-dissolving agent adopts FKN environmentally friendly gold-dissolving agent, which is a white solid powder. The main component has been detected as an organic mixture containing NiztNat-C-S, -C-N and other bonds; the calcium oxide is industrial grade and is used to adjust the slurry mass. The water for the gold leaching test is Tap water.

2.3 Test methods

The experimental sample was crushed to -2mm, and then ground using a RK/2QM 250×100 ball mill. The grinding fineness was -0.074mm90%. Then, an adjustable Stir and leach in the tank. The entire mud cyanidation of the test sample was carried out as follows: 1000 g of the test sample (-2 nm) and 1000ml of water were added to the ball mill for wet grinding. The obtained grinding product was washed with 1000ml of water into the stirring leaching tank to control the leaching process. The liquid-to-solid ratio is 2:1. After stirring and leaching for a certain period of time, extract the test sample, filter, wash (wash the filter cake 4 to 5 times with a NaOH solution with a concentration of 0.5% (z/v)), dry, analyze the Au grade in the leaching residue, and calculate the Au leaching using the following formula Rate:

Au leaching rate = (1-Au grade in leaching residue/Au grade in raw ore)×100%

3. Results and discussion

The grinding fineness was fixed at -0.074mm90% and the stirring speed of the leaching tank was 1140 r/min. The effects of slurry pH value, leaching agent concentration, slurry concentration, leaching time and temperature on the leaching effect of the new gold leaching agent were investigated; The impact of the gold leaching agent on the subsequent carbon adsorption process; and harmful detection of the tail liquid and tailing residue.

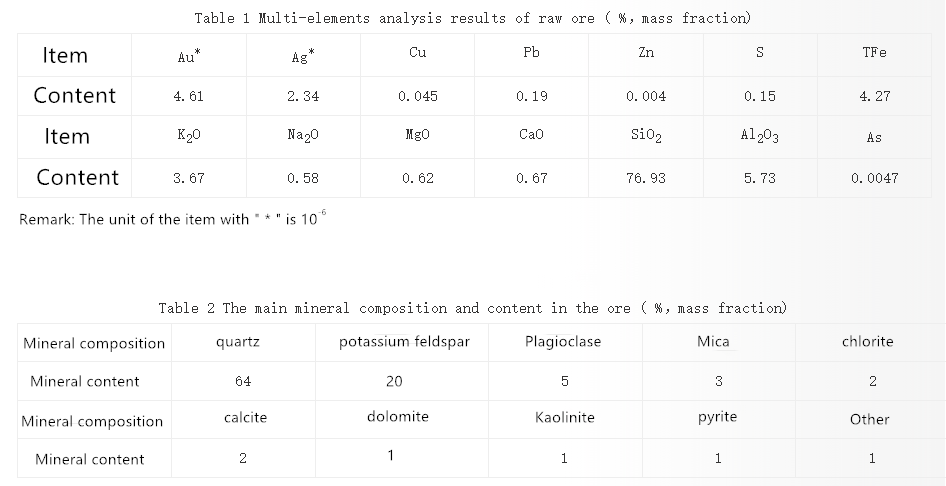

3.1 Effect of slurry pH value on gold leaching rate

Use lime to adjust the pH of the slurry to 9, 10, 11, 12, 13 and 14 respectively for the leaching test. The concentration of the slurry is 35%, the concentration of the gold leaching agent is maintained at 0.05%-0.1%, the constant temperature is 25°C, and the aeration volume is 0.6m3/L. ·h, the flooding time is 24 hours. The leaching results are shown in Figure 1. The results of the overflow test show that l in the alkaline state has a certain impact on the gold leaching effect of the new gold leaching agent, but the impact is not too great. Keep the pH between 11-12 for best results.

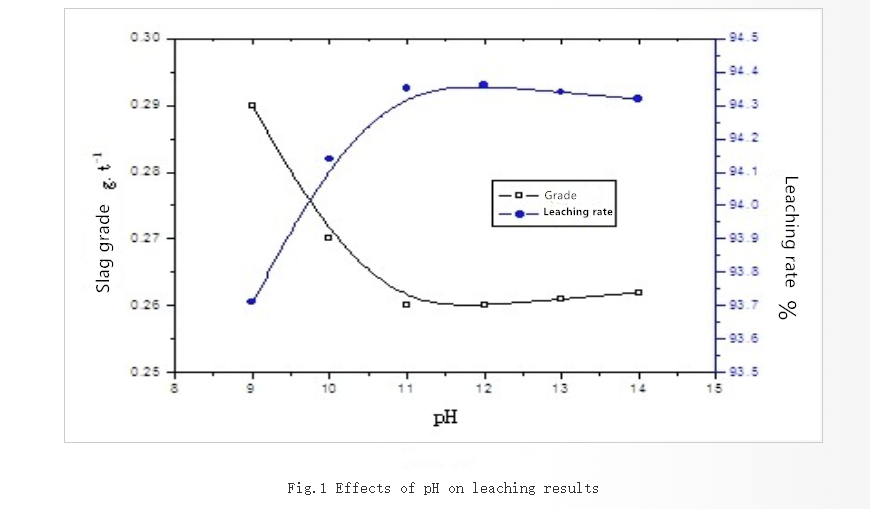

3.2 Effect of leaching agent concentration on gold leaching rate

Use lime to adjust the pH of the slurry to 11, the slurry concentration is 35%, and the gold leaching agent concentrations are maintained at 0.03%, 0.05%, 0.08%, 0.10%, 0.12%, 0.15% and 0.20% respectively, with a constant temperature of 25°C and an aeration volume of 0.6m3 /L·h, the leaching time is 24 hours. The leaching results are shown in Figure 2. The leaching test results show that FKN environmentally friendly gold leaching agent has good effects in the range of 0.03%-0.2%, and the best effect is around 0.1%. In addition, the higher the concentration of this agent, the better. When the concentration exceeds 0.12%, the leaching effect will become worse. According to past experience, when the concentration of sodium cyanide exceeds 0.15%, the leaching effect will also become worse.

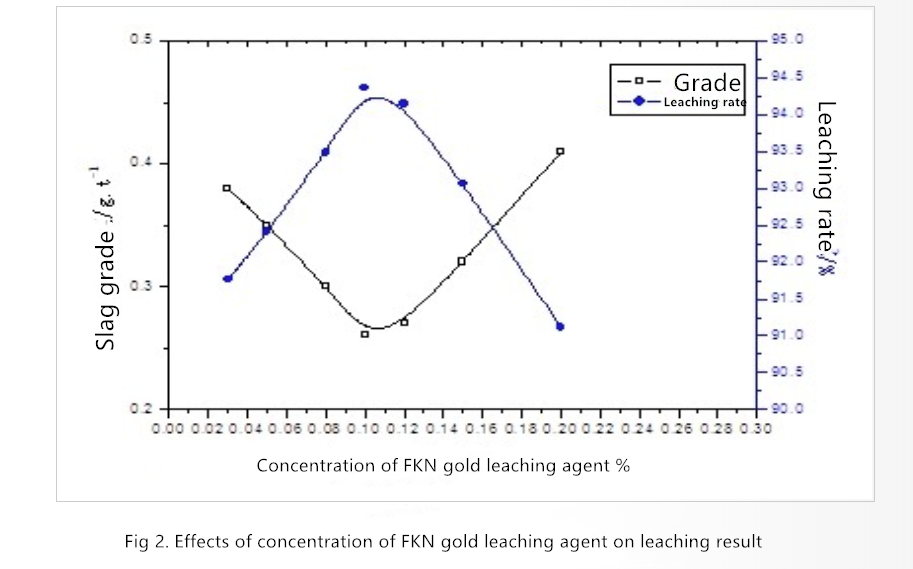

3.3 Effect of slurry concentration on gold leaching rate

Use lime to adjust the pH of the slurry to 11, the gold leaching agent concentration is 0.1%, the slurry concentration is maintained at 35%, 40%, 45%, 50% respectively, the constant temperature is 25°C, the aeration volume is 0.6m3/L·h, and the leaching time is 24 Hour. The leaching results are shown in Figure 3.

The leaching test results show that the new gold leaching agent has a good leaching effect in the range of 35%-50%. Relatively speaking, the thinner the slurry concentration, the better the leaching effect, which is basically the same as the leaching properties of sodium cyanide.

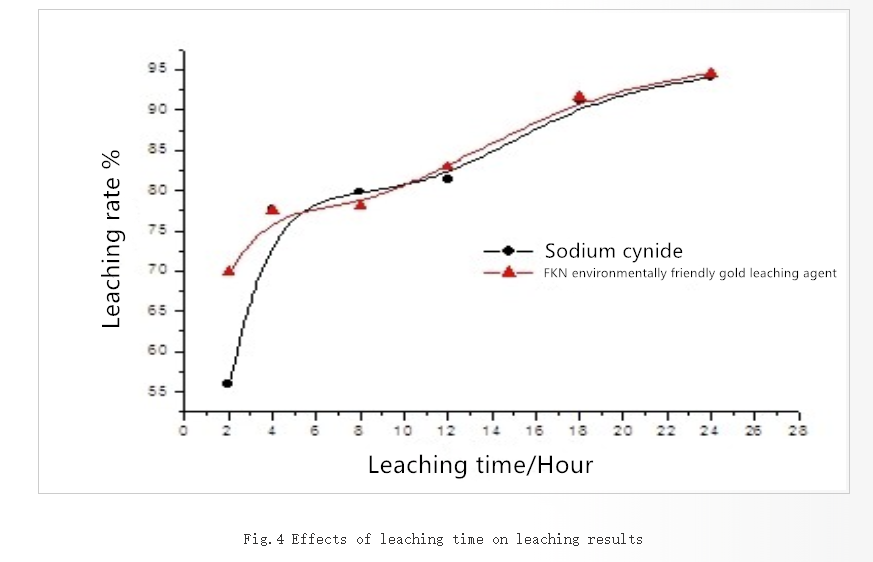

3.4 Effect of leaching time on gold leaching rate

The gold leaching agent used sodium cyanide and FKN environmentally friendly gold leaching agent respectively to conduct a comparative test on leaching time and effect. Use lime to adjust the pH of the slurry to 11. The concentration of FKN gold leaching agent is 0.1%. The slurry concentration is 35%. The constant temperature is 25°C. The aeration volume is 0.6m3/L·h. During the leaching time, samples are taken at intervals within 24 hours to analyze the grade of the leaching residue. . The leaching results are shown in Figure 4. It can be seen from the leaching results that FKN environmentally friendly gold leaching agent leaches gold faster than sodium cyanide, especially in the initial stage of the first 4 hours. This shows that the overall leaching effect of FKN environmentally friendly gold leaching agent is slightly better than that of sodium cyanide.

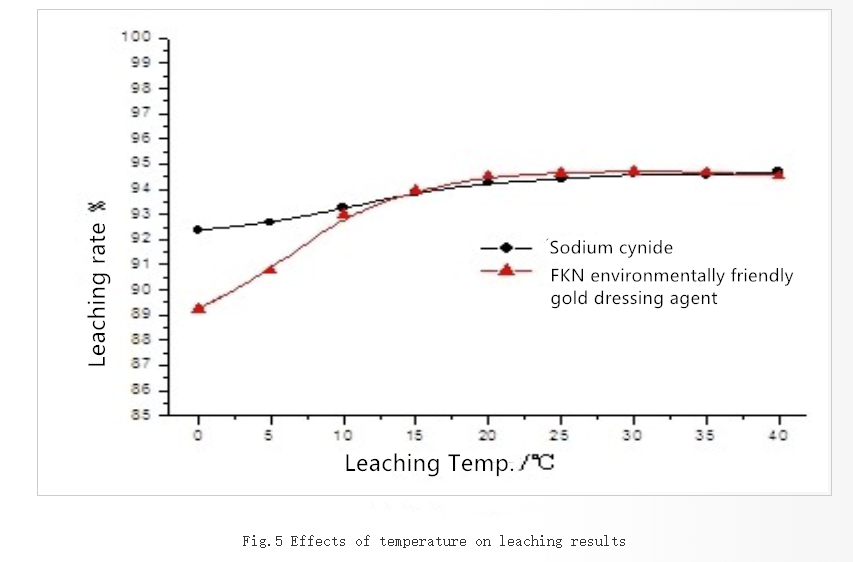

3.5 Effect of leaching temperature on gold leaching rate

In order to examine the effect of temperature on the leaching effect of FKN environmentally friendly gold extraction, leaching tests under different temperature conditions were conducted in a constant temperature box. Use lime to adjust the pH of the slurry to 11, the gold leaching agent concentration is 0.1%, the slurry concentration is 35%, the leaching time is 24 hours, the aeration volume is 0.6m L·h, the leaching environment temperature is changed from 0℃ to 40℃, and the leaching results are As shown in Figure 5. It can be seen from the test results that the leaching effect of FKN environmentally friendly gold-soluble agent is not as good as that of sodium cyanide when the temperature is below 10°C. The leaching effect becomes worse as the temperature decreases. At this time, the dosage needs to be appropriately increased; when the leaching temperature is above 10°C, the leaching effect is The effect is comparable to, or even slightly better than, sodium cyanide.

3.6 Effect of aeration amount on gold leaching rate

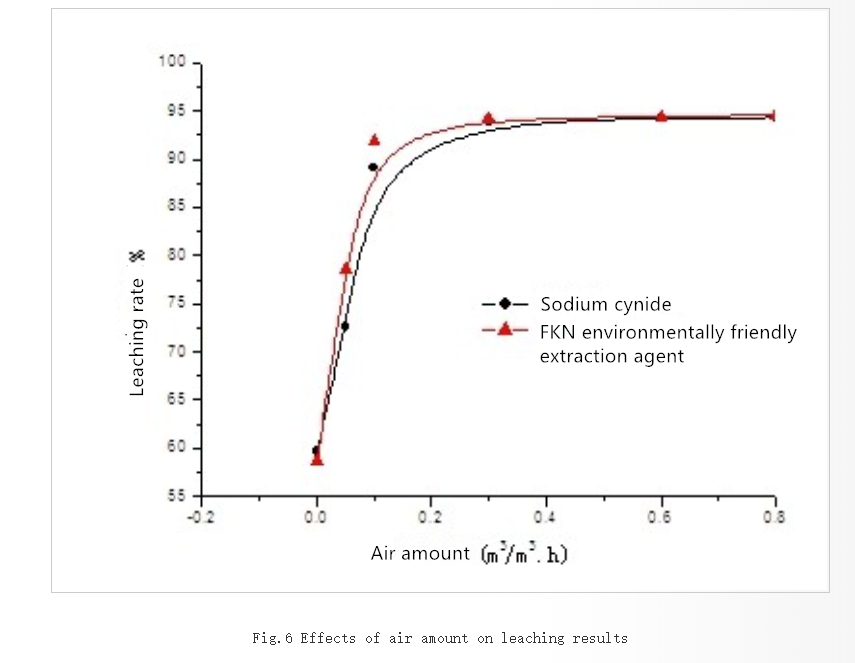

According to the data, under normal conditions, the solubility of oxygen in cyanide solution is 7-8 mg/1. When the cyanide concentration is greater than 0.03% in the leaching operation, the gold dissolution rate is mainly determined by the dissolved oxygen concentration in the slurry. Judging from the actual production process, the ideal molar ratio of cyanide to oxygen is 6:1. Sufficient oxygen can ensure the normal operation of the cyanide leaching production process and achieve good technical indicators.

In order to examine the effect of aeration amount on the gold leaching effect of FKN environmentally friendly gold leaching agent, leaching tests under different aeration amount conditions were conducted and compared with sodium cyanide. Use lime to adjust the pH of the slurry to 11. The concentration of FKN environmentally friendly gold leaching agent is 0.1%, the slurry concentration is 35%, the leaching time is 24 hours, the ambient temperature is 25°C, and the aeration volume is 0~0.8m3/m3·h. The leaching results are as follows As shown in Figure 6.

It can be seen from the test results that FKN environmentally friendly gold leaching agent has a very low leaching rate like sodium cyanide in the non-aerated state. In the range of 0-0.3 m3/m3·h, the leaching rate increases rapidly with the increase of the aeration amount. When the aeration amount After it is greater than 0.3 m3/n3·h, if you continue to increase the aeration amount, the leaching rate will increase very little and basically remain at the same level.

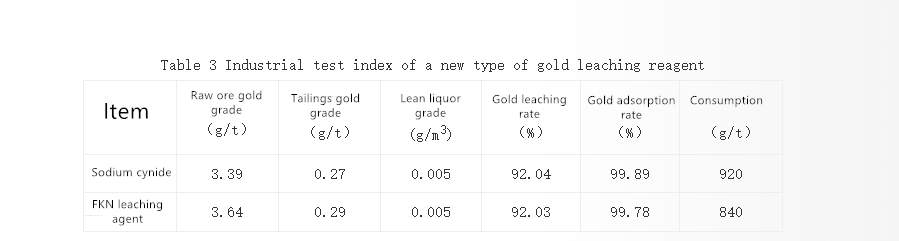

3.7 The impact of FKN environmentally friendly gold leaching agent on the carbon slurry gold extraction process

In order to examine the impact of FKN environmentally friendly gold extraction agent on the whole peat slurry gold extraction process, we conducted a 10-day carbon slurry plant in the 100t/d scale of the Hewan porphyry gold mine in Shahe Town, Fanzhi County, Shanxi Province. Industrial application tests and comparison with leaching conditions during sodium cyanide production. Industrial test parameter conditions: slurry concentration 40-45%, grinding fineness - 200 mesh 85-90%, lime-adjusted slurry pH 10-11, gold leaching agent concentration 0.1%, test results are shown in Table 3. The test data is the average result of 72 hours of continuous operation after the process is stable.

It can be seen from the industrial test results in Table 3 that under the same process conditions, the leaching indicators obtained by using the FKN environmentally friendly gold extraction agent and using sodium cyanide are basically the same. The stability of the agent is very good, and the leaching rate and adsorption rate are not inferior to those of cyanide. Sodium chloride.

3.8 Detection of harmfulness of tailings

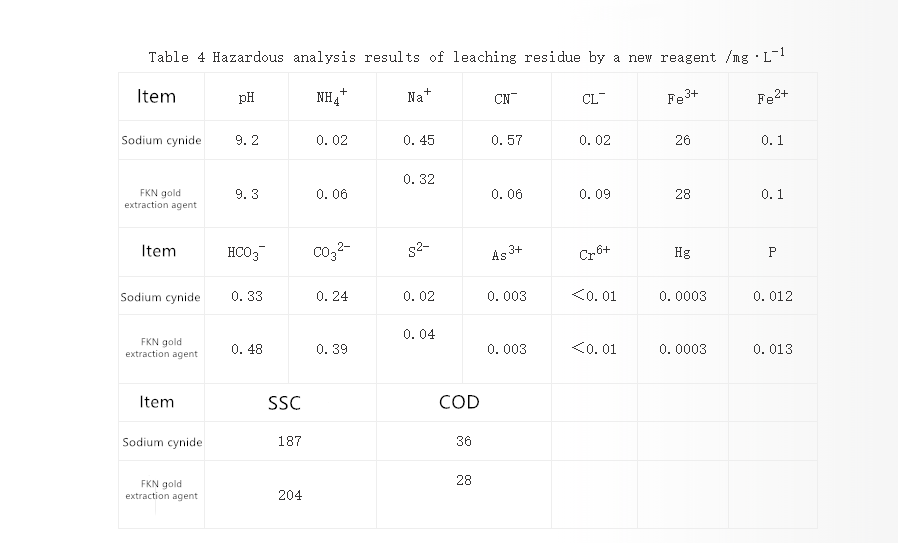

In the industrial production of cyanide gold extraction, the presence of highly toxic cyanide radicals in the tailings is a headache. Even if dry discharge after washing and filtration is used, the disposal of tailings reservoir drainage in the rainy season still needs to be considered. Many large gold mines The mineral pulp plant spent huge sums of money to build a tailings pond accident wastewater treatment station, resulting in increased production costs. In order to examine the presence of FKN environmentally friendly gold dissolving agent in the tailings, we took the tailings produced during the 100t/d scale industrial test, conducted harmful testing, and compared it with the sodium cyanide gold leaching tailings. The tailings slurry is concentrated, filtered and washed twice. The filtrate and washing liquid are returned to the system for recycling, and the filter residue is discharged dry into the tailings reservoir. In the test, the filter residue was taken out from the tailings reservoir, mixed with distilled water to form a slurry with a mass concentration of 50%, stirred and soaked for 72 hours. After clarification, the supernatant was taken for harmfulness testing. The test results are shown in Table 4.

It can be seen from the test results in Table 4 that the sodium cyanide leaching tailings also contain relatively high levels of cyanide, and the cyanide concentration in the slurry prepared with a concentration of 50% reaches 0.57 mg/L. This shows that even if the cyanide tailings are washed and filtered Afterwards, it is discharged dryly into the tailings pond. If not treated, excessive sodium cyanide solution will still be formed after encountering rainwater, and it cannot be discharged without treatment. However, the cyanide radical in the tailings leached by FKN environmentally friendly gold leaching agent is very low, and it is formulated to a concentration of 50%. The cyanide concentration in the slurry is only 0.06 mg/L, which is almost undetectable. It can be safely stored after dry discharge into the tailings pond, and will not form harmful cyanide-containing wastewater with rainwater. Other harmful ingredients are also very low.

4. Conclusion

(1) For the leaching process of oxidized gold ores, this study evaluated the gold leaching effect of FKN environmentally friendly gold leaching agent from various aspects such as slurry pH, slurry concentration, gold leaching agent concentration, leaching temperature, aeration volume, and leaching time. According to the investigation, the leaching effect is basically the same as that of sodium cyanide, and the gold recovery rate and chemical consumption are not inferior to those of sodium cyanide.

(2) Due to the short period of industrial testing, the long-term recycling use of FKN environmentally friendly gold extraction agent needs to be further investigated in the production process.

(3) Analysis of the hazards of tailings shows that the tailings produced using this agent have very low cyanide content after dry discharge and are not harmful to the environment. From an environmental protection perspective, it is worthy of vigorous promotion.

(4) Through the above analysis, FKN gold dressing agent can replace NaCN so long as the the appropriate process parameters are used in the carbon in pulp process.